Certificate III in Engineering - Fabrication Trade Sheetmetal Working

Sorry, this course is not available for international students.

If you are a local student you may be eligible.

To find a course that's available to international students, please visit the search page:

Overview

4 years part time

Ongoing

Master sheet metal working techniques

Equip yourself with the skills to thrive in Australia’s massive metal fabrication industry. The Sheetmetal Working stream of our Certificate III in Engineering Fabrication Trade MEM31922 helps you master sheet metal working techniques with an emphasis on practical learning. Learn to be the best from the best by studying at an institution named as a Top Welding Training Organisation by Weld Australia. You’ll perfect skills such as marking out geometric patterns, cutting, forming, shaping, welding and polishing metal to food grade standards.

Practice specialised fabrication processes

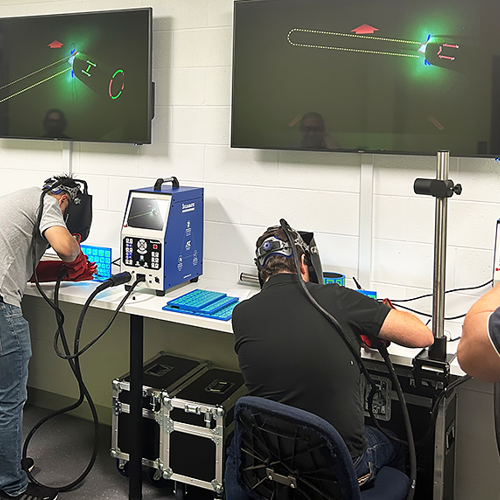

You’ll benefit from Melbourne Polytechnic’s resources, including a purpose-built, fully equipped fabrication workshop, computer lab and welding workshop. You’ll be trained to use special-purpose machinery such as computer numeric controlled guillotines and press forming equipment. Practicing in state-of-the-art facilities under the guidance of industry-experienced teachers, you’ll quickly gain the confidence and knowledge to advance in this specialised industry.

Open up multiple paths for your future

Once you complete this course, you can work in a variety of settings from small workshops to large industrial factories. With an annual turnover of $29 billion and contributing $11 billion to GDP, the steel industry is one of Australia’s most important industries. You’ll graduate with skills that’ll make you an asset in your workplace and position you as an in-demand tradesperson, whether you go on to work in building and construction, mining, agriculture, oil and gas drilling or another industry.

Career Pathways

Where will the Certificate III in Engineering - Fabrication Trade - Sheetmetal Working MEM31922 take me?

The Certificate III in Engineering – Fabrication Trade MEM31922 (Sheetmetal Working) is a nationally recognised qualification, and will open the door onto a job as a metal fabrication tradesperson in the metals and engineering industry Australia-wide.

- Welder

- Sheetmetal Worker

- Manufacturing Tradesperson

- Metal Fabricator

Study Pathways

Graduates of this course have the opportunity to further their studies through a diverse range of specialisations, encompassing Certificate IV programs, Diplomas, and a variety of short courses.

Course Details

Delivery methods

The training is delivered for 38 days per year over a 3-year period (114 weeks). The day release training contains a mixture of theory and practical components.

How you will study

Each course has a dedicated learning method that is designed to let you thrive in your studies.

On-campus

Interactive learning in a face-to-face environment. Classes will be held at a Melbourne Polytechnic campus or partner institute. Visit the How You'll Study page for more information.

Assessment Methods

Written or online knowledge assessments, observation of skills, completion of relevant industry based projects

Units of Study

The hours displayed are nominal, actual classroom hours delivered may differ. Please contact us for the latest student contact hours information.

| Code | Subject | Elective | Hours |

| MEM05004 | Perform routine oxy fuel gas welding | Elective | 20 |

| MEM05005 | Carry out mechanical cutting | Elective | 20 |

| MEM05006 | Perform brazing and/or silver soldering | Elective | 20 |

| MEM05007 | Perform manual heating and thermal cutting | Elective | 20 |

| MEM05010 | Apply Fabrication, Forming And Shaping Techniques | Elective | 80 |

| MEM05012 | Perform routine manual metal arc welding | Elective | 20 |

| MEM05037 | Perform Geometric Development | Elective | 60 |

| MEM05049 | Perform routine gas tungsten arc welding | Elective | 20 |

| MEM05050 | Perform routine gas metal arc welding | Elective | 20 |

| MEM05052 | Apply Safe Welding Practices | Elective | 40 |

| MEM05056 | Perform routine flux core arc welding | Elective | 20 |

| MEM05085 | Select welding processes | Elective | 20 |

| MEM05089 | Assemble fabricated components | Elective | 80 |

| MEM05090 | Weld using manual metal arc welding process | Elective | 40 |

| MEM05091 | Weld using gas metal arc welding process | Elective | 40 |

| MEM05094 | Repair, replace and/or modify fabrications | Elective | 40 |

| MEM08010 | Manually finish/polish materials | Elective | 60 |

| MEM09002 | Interpret technical drawing | Core | 40 |

| MEM11011 | Undertake manual handling | Core | 20 |

| MEM12007 | Mark Off/Out Structural Fabrications And Shapes | Elective | 40 |

| MEM12023 | Perform engineering measurements | Core | 30 |

| MEM12024 | Perform computations | Core | 30 |

| MEM13003 | Work safely with industrial chemicals and materials | Elective | 20 |

| MEM13015 | Work safely and effectively in manufacturing and engineering | Core | 40 |

| MEM14006 | Plan work activities | Core | 40 |

| MEM16006 | Organise and communicate information | Core | 20 |

| MEM16008 | Interact with computing technology | Core | 20 |

| MEM17003 | Assist in the provision of on-the-job training | Core | 20 |

| MEM18001 | Use hand tools | Core | 20 |

| MEM18002 | Use power tools/hand held operations | Core | 20 |

| MEM24001 | Perform basic penetrant testing | Elective | 20 |

| MSMENV272 | Participate in environmentally sustainable work practices | Core | 30 |

Attend an Information Session

Fees & Costs

| Concession | Government subsidised fee | Non-subsidised fee | |

|---|---|---|---|

| Tuition fee | $1250 | $6250 | $26250 |

| Maximum annual amenities | $175 | $250 | $250 |

| Total payable | $1425 | $6500 | $26500 |

| Per year | $0 |

| Per semester | $0 |

The student tuition fees as published are subject to change given individual circumstances at enrolment.

Displayed course fees are indicative only. There are many variables that impact the total amount of your full course costs including qualification for government subsidies, concessions or recognition of prior learning. Tuition fees do not include the cost of student amenities or material costs.

This training is delivered with Victorian and Commonwealth Government funding. Contact us to find out if you’re eligible for a Government subsidy.

Melbourne Polytechnic offers a range of payment options to help you pay your tuition fees, so you can get on with your studies.

Fees displayed are effective for new applications received on or after 1st of November. Tuition fees do not include textbooks, course materials or overseas student health insurance and visa fees.

After initial deposit, international students are able to pay tuition fees in installments, four times per year.

For more detailed information please read the International Student Fees.

Fees explained

The fees for those ineligible for a government-funded enrolment.

The cost of tuition for those eligible for government funding.

Concession fees are charged at 20 per cent of the standard fees for enrolments in Certificate I to IV courses. To be eligible students must meet Skills First eligibility criteria and present a valid:

- Commonwealth Health Care card, or

- Pensioner Concession card, or

- Any dependent spouse or dependent child of one of the above cardholders, or

- Veterans Gold card.

The following groups are eligible for concession fees from Certificate I to Advanced Diploma level:

- Aboriginal and Torres Strait Islander students

- Asylum Seekers and victims of human trafficking

Additional expenses

The Student Services and Amenities Fee is charged at forty cents (40 cents) per student contact hour and is capped over a twelve (12) month period, effective from the enrolment date, to:

- $250 for full fee-paying students; and

- $175 for concession-paying students studying Certificate I, II, III, or IV.

Amenities fees are used to improve non-academic services including libraries, counselling services, student support, and recreational activities.

- Student workbooks and resources

- Basic writing materials including a notebook and pens.

- Appropriate PPE for engineering workshop

- Other equipment and materials needed and additional information will be given to you by the teaching department at time of enrolment or class induction.

Course Fees

Fees are calculated on a case by case basis.

Requirements

The learner must be engaged as an apprentice under a training contract. A short literacy and numeracy test is required to be completed at enrolment.Next Steps

Apprenticeships are coordinated via the Trade and Traineeship Support Unit (TSU) where you will provide details of your employer, who will register you with an Australian Apprenticeship Support Network (AASN) provider.

The AASN will register your training contract with EPSILON and you will be allocated an EPSILON number. Melbourne Polytechnic will then be able to enrol you into your training program.

If you have any questions about the application procedures for an apprenticeship, please contact the TSU.

Recognising Organisations

Nationally Recognised Training This course is government accredited and has national recognition.

Local student means; you are an Australian citizen or permanent resident, a New Zealand citizen or a permanent humanitarian visa holder.